Well known machines - with a twist

Two well-known DALBO machines have been modified to better suit English conditions.

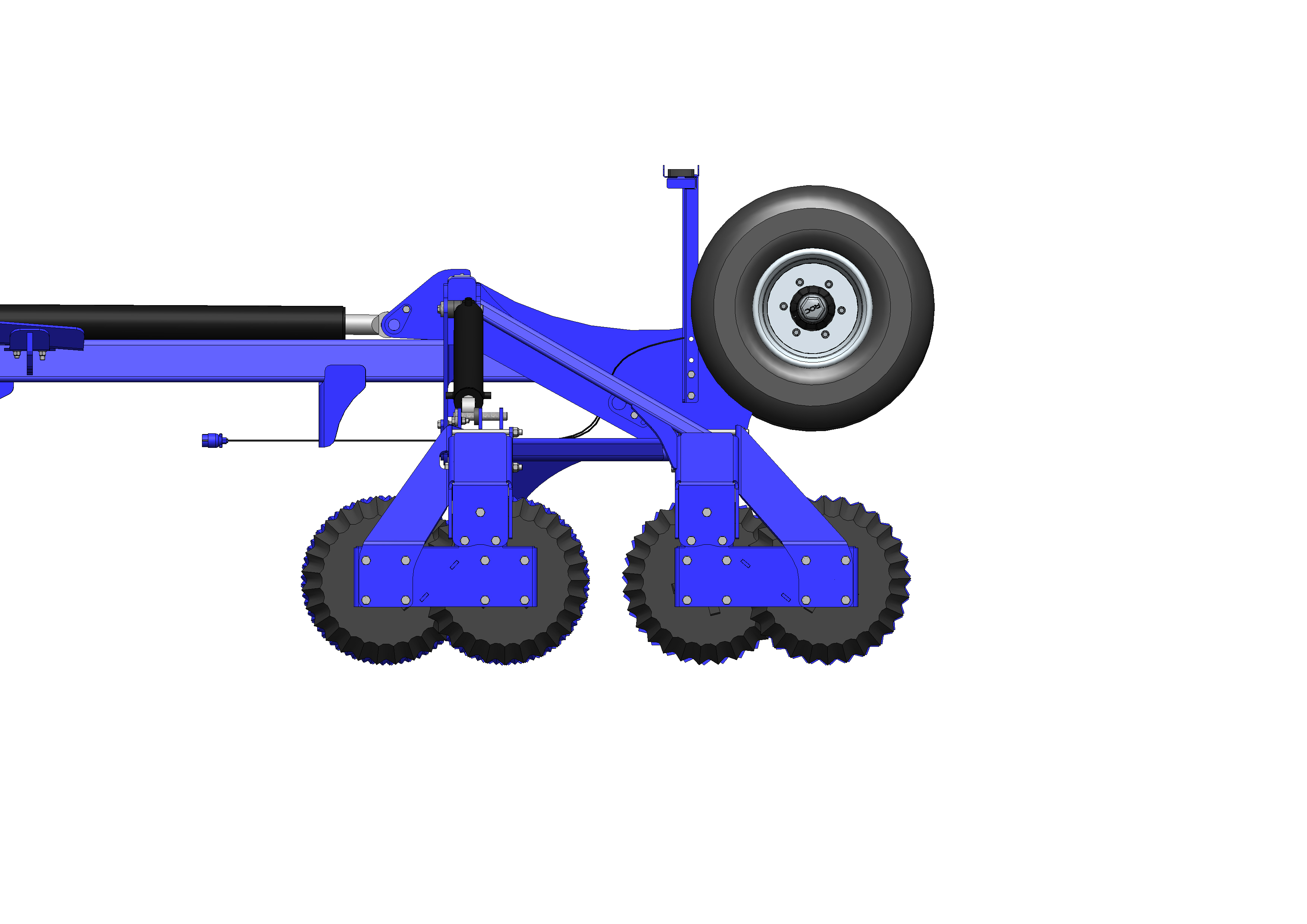

TRIMAX 'P'

TRIMAX ‘P’ is primarily designed to work potato land, both post harvest and for spring cultivation. TRIMAX ‘P’ is based on the very successful TRIMAX range of stubble cultivators.

The robust frame construction of HD box section with 90 cm under beam clearance allows material to flow easily through the machine. The TRIMAX ‘P’ is equipped with our tried and tested specially designed 3D hydraulically protected auto reset (NSH) legs.

The 3 rows of tines, 11 in total, are mounted with a choice of reversible points. As standard the machines is fitted with 50 mm wide points, but 60 mm, 80 mm or a winged share option are also available. Behind the tines a 50cm diameter cage roller is mounted for consolidation and depth control.

The TRIMAX ‘P’ is an ideal machine to run through harvested potato ground or as part of the spring seedbed preparation. TRIMAX ‘P’ is an effective, fast, efficient, easy to pull cultivator that can work at depths of between 5 and 30 cm.

The TRIMAX ‘P’ is also available as a mounted machine in working widths of 4.1 m and 5.2 m.

MULTIROLL TWIN

MULTIROLL TWIN is a new HD system roller from DALBO.

The 630 and 830 model is mounted with a double row of heavy duty 60 cm Cross Combi rings. The versatility of the MULTIROLL system is that it is easy to fit different ‘tools’ in front of the rings via our ‘quick fit’ mounting bracket. For example when fitted with a cracker board the MULTIROLL TWIN has a minimum weight of 880 kg’s per metre which makes it an ideal machine to use directly onto ploughed land and to use as part of a seedbed preparation system. When we mount our 3 rows of HD 16mm tines the machine is ideally suited for use on grassland maintenance and for direct use onto stubble. Add a seeder to the machine and you have a machine capable of doing a number of tasks in a single pass.