A wide selection of rings

DALBO offers a wide range of roller rings – tailored to all soil types and cultivation methods.

Whether you're working with light sandy soil or heavy clay, we have the right solution to ensure optimal packing and efficiency in the field.

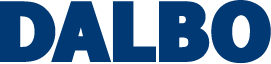

The name of our SNOWFLAKE® ring is derived from the unique design that looks like a snowflake. Without a change in weight or material, the design of SNOWFLAKE® rings gives 6 times the strength of a conventional Cambridge ring, and therefore we offer an impressive 6-year warranty on the SNOWFLAKE® ring. The design of the SNOWFLAKE® ring is patent protected.

The SNOWFLAKE® ring is suitable for all purposes, both before and after sowing. The special properties of the ring's wide shoulder and wavy outer profile give a good result and uniform pressure when you roll crops. The wide shoulders support the weight better, and the outer protrusions leave small indentations in the ground before sowing. This makes the field more robust to wind and weather and provides good drainage of the field. In addition, the SNOWFLAKE® ring has the advantage that it provides a good drive for the roller when working in dry sandy soil. When choosing the size of the ring, the starting point is that the heavier the soil, the larger the diameter needed. By choosing a larger ring diameter, a greater ground pressure and less wear as well as a better ability to push stones down is achieved. The breaker rings have a loose fit on the shaft, which allows them to move freely and thus ensure a good cleaning under most conditions.

In combination with intermediate serrated rings, the SNOWFLAKE® ring gives a good result when working on dry, uneven ground, and in these situations it is recommended that a hydraulic cracker board be fitted in front of the roller. This provides a great combination of crushing of clods as well as better levelling of the field.

Last but not least, the SNOWFLAKE® ring is suitable for rolling, levelling and compacting established grasslands. Freshly sown grass seeds will benefit from being rolled, which ensures good seed to soil contact.

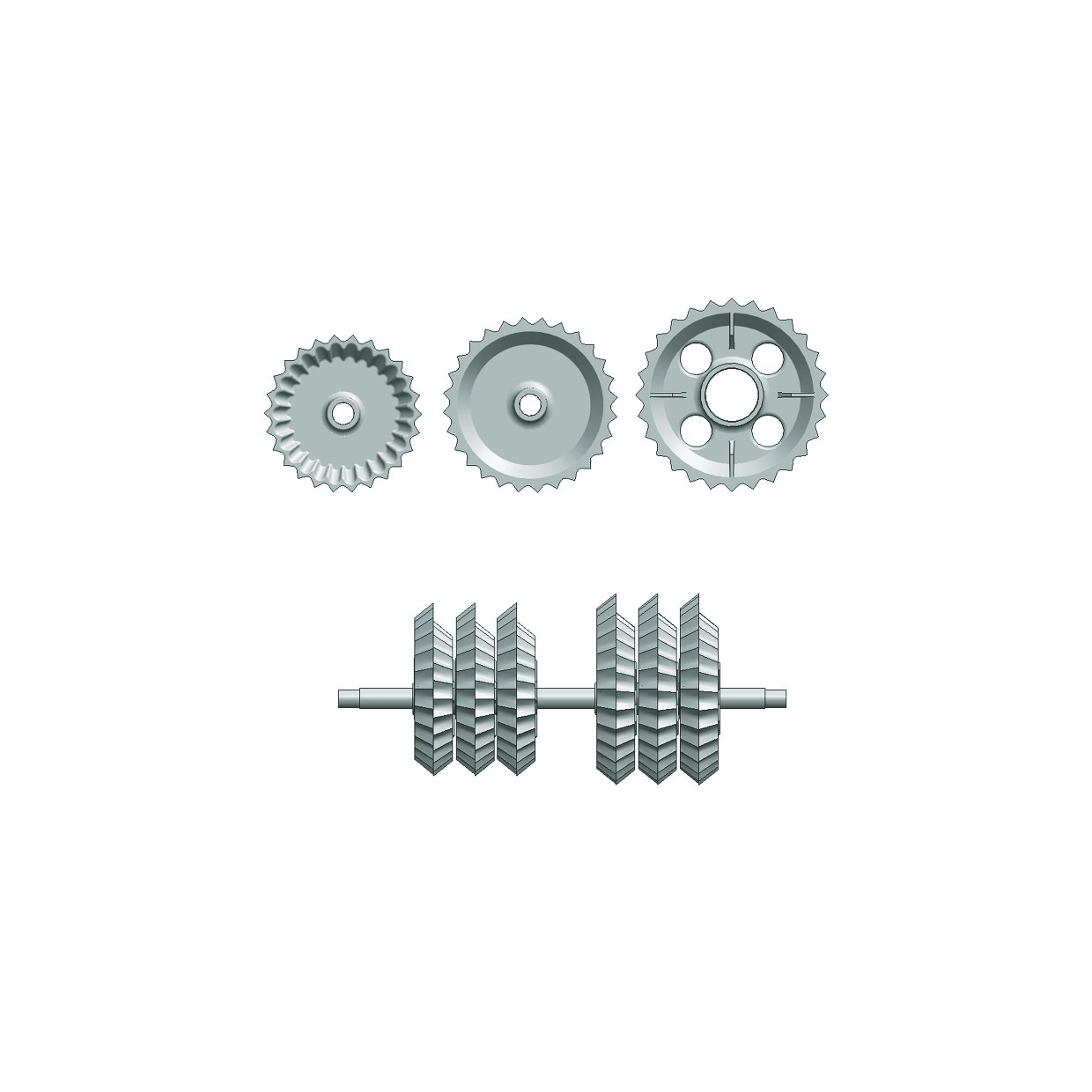

A big advantage of the Cross Combi rings is their ability to stay clean, as every other ring sits loosely on the shaft. Another advantage of the Cross Combi rings is that they press both downwards and to the side, which increases the contact between seed and seedbed. Cross Combi rings, like SNOWFLAKE® Cambridge rings, can be supplied with different diameters, where the same principles apply.

With its aggressive movements and star profile, the Cross Combi ring is very suitable for seedbed preparation, as it helps to incorporate the seed into the seedbed. In addition to rolling, the interaction between the rings helps to crumble the soil, resulting in the topsoil layer being light and airy, providing drainage while the soil is packed at depth.

This provides a uniform sowing depth, which creates the best conditions for good root development. This tillage reduces the risk of surface hardening and a crust formation after rain. It is recommended to have a hydraulic cracker board mounted on the roller if the ground is lumpy. This gives both a really good levelling of the surface as well as shattering of dry clods.

The aggressive roller effect of the Cross Combi ring is also incredibly suitable for destroying thick stubble, especially when combined with a front-mounted knife roller on a MAXIROLL.

When used for grass rolling, the Cross Combi rings will help stimulate the germination of grass.

In areas where large areas of maize are grown, farmers are increasingly facing the problem of the corn borer beetle. The beetle can easily overwinter from year to year and infect crops in subsequent years. To minimize beetle reproduction, it is good practice to destroy the corn stalks by splitting or cutting the stalk between each section. This reduces the risk of the beetle overwintering. An ideal tool for use against the beetle is Cross Combi rings mounted on the heavy MAXIROLL roller together with a front-mounted knife roller. The knife roller, together with the Cross Combi ring, will cut and split the corn stubble, making it an unsuitable wintering place for the corn borer beetle. The high quality of the castings on our Cross Combi rings allows us to offer a 3-year warranty.

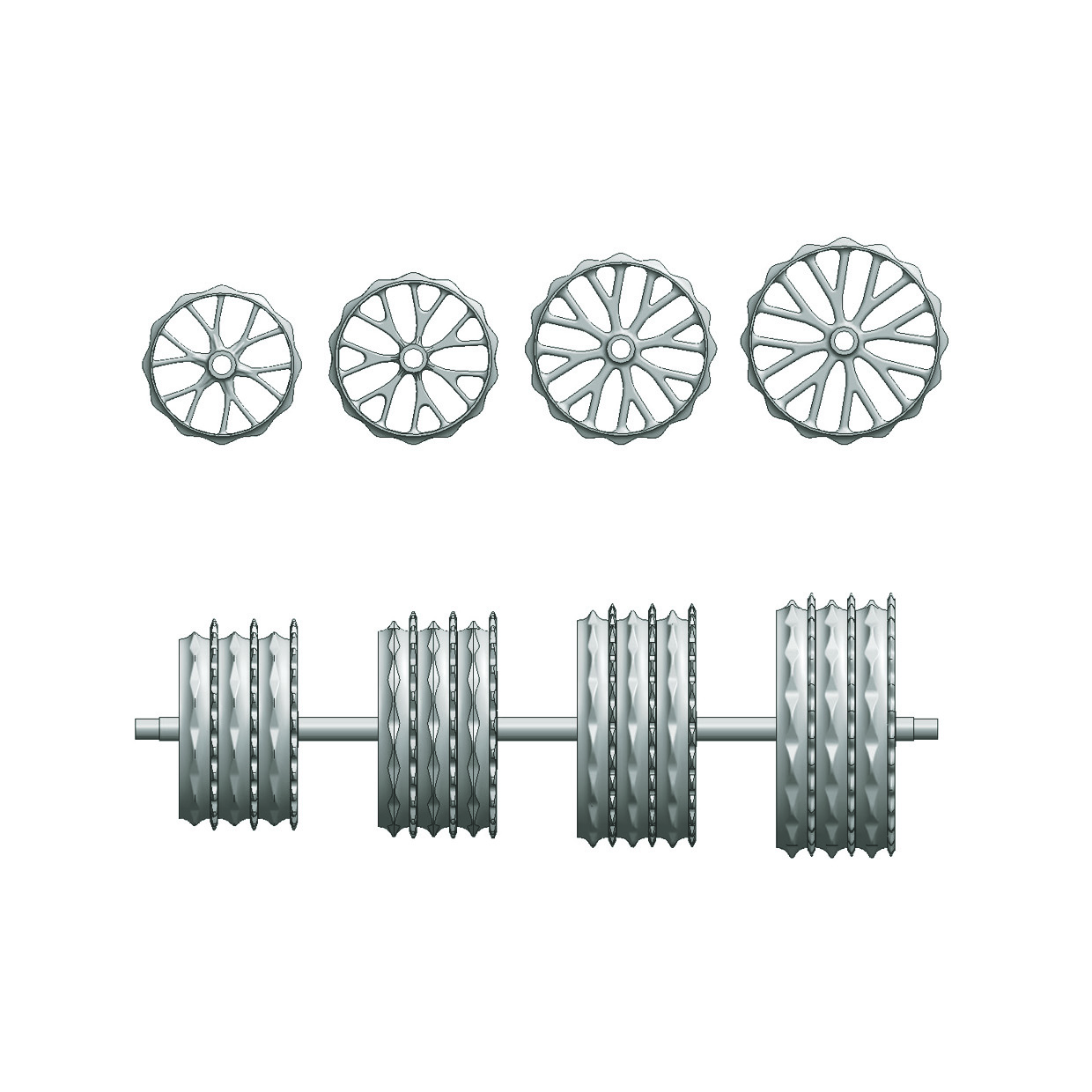

The Crosskill rings are always mounted on the axles in pairs using one large and one small ring. The small ring is in a fixed position, while the large ring moves freely. The large ring has a much larger centre hole, which allows it to move freely approx. 6 cm upwards when it rotates.

This movement means that the Crosskill rings are self-cleaning. The Crosskill ring is excellent for seedbed preparation. For most soil types, the rings work well in a MAXIROLL frame with a hydraulically adjustable cracker board, as this combination creates a good seedbed directly from the ploughed field. The Crosskill ring is also fantastic in a DALBO roller that is pulled behind a towed seedbed cultivator, leaving an ideal seedbed with a firmer soil layer at the bottom and with a loose and crust-resistant soil layer at the top. The high-quality casting of our Crosskill rings allows us to offer a 3-year warranty on the rings.